Haven’t you always wondered how the many precious and high-quality raw materials in our CAPS beauty & hair actually get into those little capsules? What work goes into it, and what’s really important to remember during manufacture?

Well this is where you’ll get all the answers! We’ve got a photo feature for you about the production of our CAPS beauty & hair – with exclusive behind-the-scenes insights guaranteed!

Get your lab coat on!

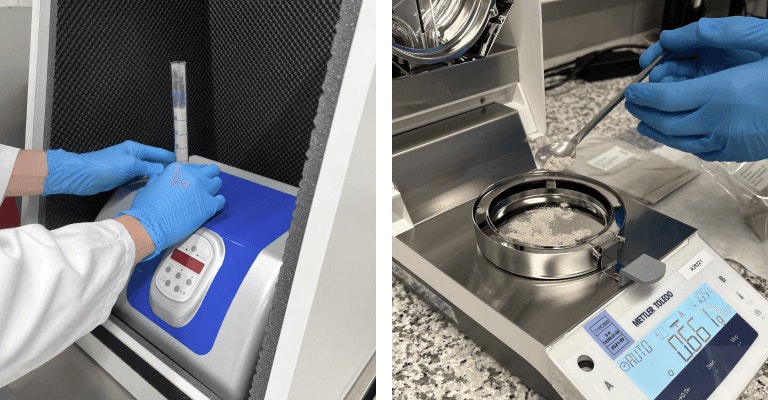

Firstly, it’s essential to pay attention to hygiene rules and dress yourself accordingly. Lab coat, hairnet, mask and gloves are a must – because nothing can be allowed to get into the CAPS that shouldn’t be in there. Our Research & Development Department does fantastic work, and develops unbeatable formulations. With the stringently-observed hygiene concept (from which our camerawoman wasn’t exempted either…) we can truly ensure that apart from the ingredients that are intended for the formulations, no disruptive substances get into the mix.

Let’s start

To start off, naturally all of the raw materials – such as apple fruit extract and others – have to be on hand, and are prepared for their upcoming processing. All of the ingredients are weighed with absolute precision.

Hydroxy…. what?

That includes the empty capsule cases made of hydroxypropyl methyl cellulose. Sounds complicated, but it isn’t at all! It’s actually a processed variant of the natural plant substance, cellulose. So the capsule cases are entirely vegan and are completely safe for human consumption, so the capsules can be taken without any concerns. That’s because, like a water-soluble fibre, hydroxypropyl methyl cellulose – or HPMC for short –is excreted from the body undigested.

Sieving and mixing

We buy all of the ingredients for our CAPS in powder form. With the help of machines, they are sieved and mixed together well.

Quality check

The next step involves extensive quality testing.

How does the powder get into the capsule case?

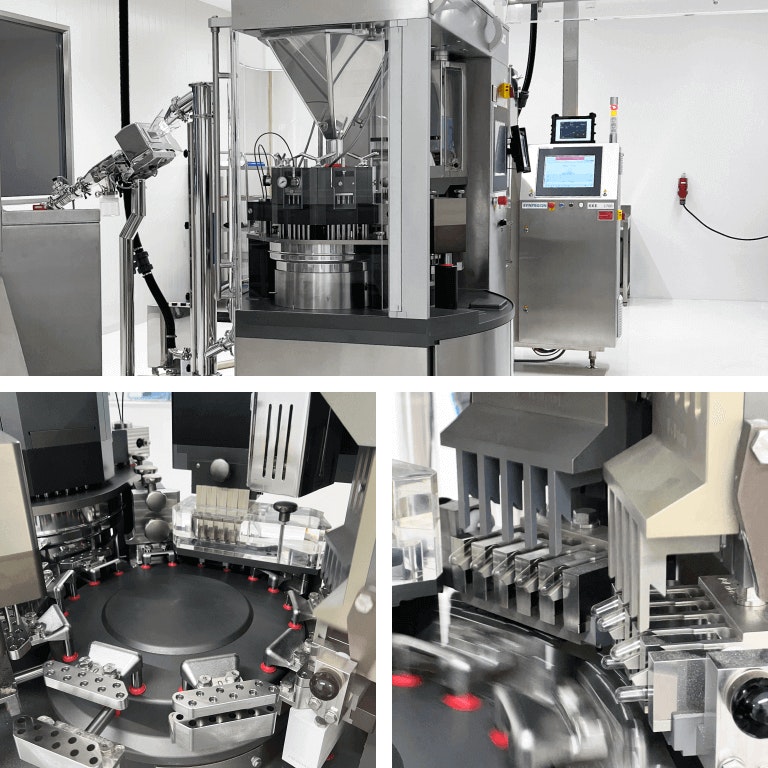

Now the mixed, highly effective powder has to be put into the capsule cases. Bet you’re wondering how that’s done? Quite simple: we use a fantastic machine that makes our lives so much easier. It doesn’t just fill the capsules, it seals them shut as well.

How do the capsules get into the tin?

The filled capsules shoot out of the machine and land directly in a container that is carefully sealed for their “transport” to the next step of production. Although the CAPS beauty & hair are finished, naturally they can’t go out on sale in their present condition. So, firstly, they have to be packaged in our eco-friendly tins.

This step also takes place in the Production Department, but in a different area because, from this point onwards, the actual development and manufacture of the products is already in the past, and we are now focused on preparing them for sale. We have the support of a machine for this step too. Firstly a huge number of tins are moved by the machine until they are finally lined up in a row on a conveyor belt. Each tin stops underneath the opening for filling and – in the case of CAPS beauty & hair – is automatically filled with 90 capsules.

Sealing, packaging and labelling

Now manual work comes into play. The filled tins are now sealed by hand with lids which already contain a round foil. In this step, the stickers with batch number and best-before date are also stuck to the bottom of each tin by hand. That concludes all of the production steps, and now the tins move on to be packaged.

This is where the labels with the freshness seal are stuck onto the tins.

And finally the CAPS beauty & hair are enclosed in their outer packaging, together with the accompanying leaflet, so that they’re ready for you to buy them.

Zur Übersicht

Zur Übersicht